Image source, Francesco Clark

Image source, Francesco ClarkImage caption,

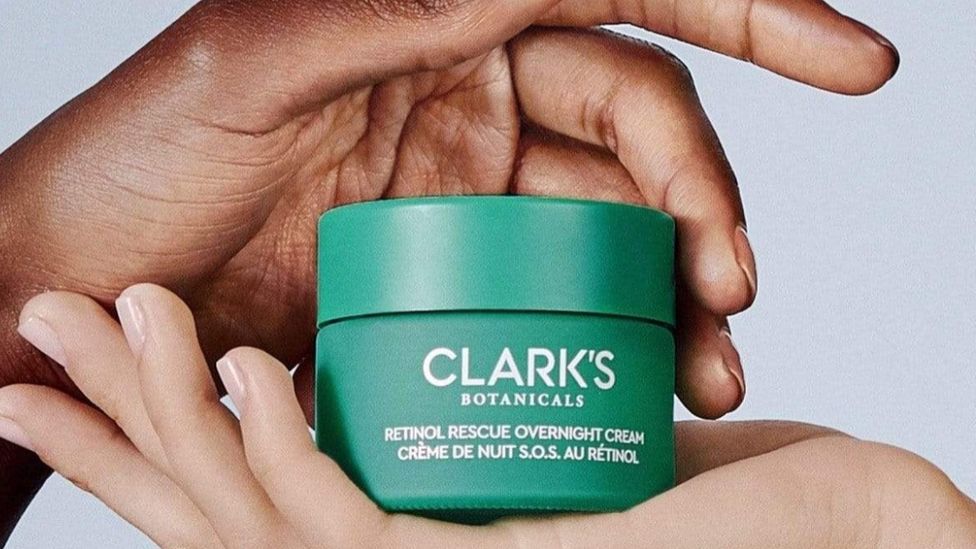

Inspiration to start up a business can come from anywhere, but for Francesco Clark it was the result of a life-changing injury.

Back in 2002, the then 24-year-old was paralysed in a diving accident. In addition to losing the use of his legs, the spinal cord injury caused his skin to no longer be able to sweat.

With his skin subsequently prone to becoming irritated, he and his father, a doctor and homeopath, developed some natural face creams in their home kitchen in New York State.

It was the start of a skincare business called Clark’s Botanicals, which is now reported to have annual revenues of around $5m (£4.2m).

Image source, Clarks’s Botanicals

Image source, Clarks’s Botanicals Image caption,

Mr Clark grows some of the natural ingredients for his skin creams, such as jasmine and aloe vera, in his own garden at home in Westchester County, north of New York City.

The rest he sources as locally as possible, with production outsourced to nearby facilities rather than seeking cheaper manufacturing overseas.

“Everything is made here in the US,” Mr Clark says. “That’s very important to me, that we maintain the independent and local sense of development for the brand.”

Mr Clark says that using local suppliers and factories has meant that his company has been able to avoid the widely reported global supply chain delays of the past two years.

Image source, Getty Images

Image source, Getty ImagesImage caption,

These were caused firstly by the Covid-19 pandemic resulting in staff shortages at factories and ports in China and other countries, and also on cargo ships.

Then there was the six-day closure of Egypt’s Suez Canal, a key global trade route, in 2021. And this year the conflict in Ukraine and resulting sanctions against Russia caused turbulence in the markets for crude oil, natural gas, cooking oil and flour.

Meanwhile, the UK and other European countries have seen a shortfall of lorry drivers.

For these assorted reasons a growing number of companies on both sides of the Atlantic have reportedly been looking at reshoring their supply chains, by finding new suppliers in their home countries.

Image source, Getty Images

Image source, Getty ImagesImage caption,

Mr Clark says that in addition to avoiding delays, having suppliers much nearer to you means you can build closer relations with them. He adds that this results in them doing more for you, such as meeting tighter deadlines if required.

“When you’re making things locally, you’re also able to lean on the people that you’ve been working with… you’re able to say, ‘I’m so sorry but we need this next week’.”

Looking back at the start of the pandemic Mr Clark says this explains how his company was able to start producing hand sanitizer “from concept, to shipping to customers, within eight days”.

He adds: “We were able to pivot extremely quickly because of the incredible partnerships that we have with our manufacturers and the talented team at Clark’s Botanicals.”

New Economy is a new series exploring how businesses, trade, economies and working life are changing fast.

Supply chain expert Lisa Anderson says the global system has never been more volatile.

“It’s an unprecedented situation because demand fluctuation has been so dramatic,” says the president of LMA Consulting Group, a California-based supply chain management consultancy.

At this stage it is far from clear when the global supply chain will return to more normal conditions. The war in Ukraine shows no sign of coming to a conclusion any time soon, and the coronavirus continues to cause problems.

A new Covid-19 outbreak prompted a 65-day lockdown in Shanghai earlier this year and resulted in disruption at Shanghai’s port, the world’s busiest.

“If you [a company] are hit by a disruption, then you can lose up to half of your profits over a year, because of a single disruption,” says Dr Güven Demirel, lecturer in supply chain management at Queen Mary University of London.

“Previously, there were isolated disruptions, small operational risks. But now, if we think about the past three to four years, we have had a pandemic, we have had Brexit, and now there is a war in Europe. So it is hitting many firms and supply chains.”

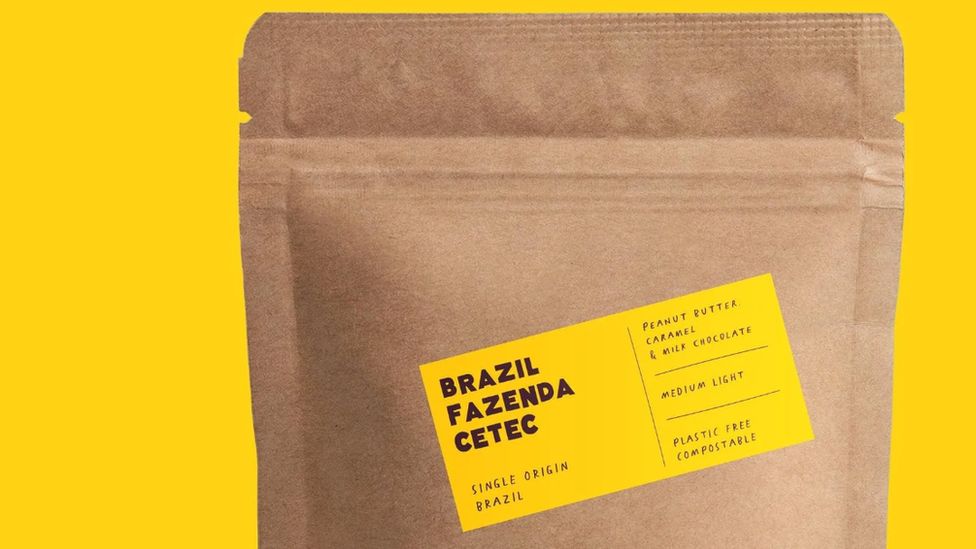

Some industries and companies are more reliant upon global supply chains that others. One such firm is UK coffee business Alpaca Coffee, whose beans obviously originate from warm coffee-growing countries.

Image source, Alpaca

Image source, AlpacaImage caption,

Founder and owner Victoria Poon says the global coffee industry is an interconnected web of farms, roasters and customers, located several continents away from each other. So when one part collapses, others can follow. “It’s like a domino effect,” she adds.

Alpaca Coffee already grapples with lead times of several months. “When you have to product plan it does take time,” Ms Poon says. This means that last month her team was already planning the details of Alpaca’s Christmas blend.

“[And] one of the challenges we’ve been seeing is the rise of coffee prices,” Ms Poon adds.

“Now what we have to do is make sure that we’re on top of inventory.”

But while Ms Poon has to buy her coffee beans from overseas, she can see the benefit of buying local for the other things that the Portsmouth-based company needs.

Image source, Alpaca Coffee

Image source, Alpaca CoffeeImage caption,

Recently she says she tried to order custom-made, branded cups for the firm’s new pop-up physical shop in Soho, London. Called Café Alpaca. It opened at the start of this month.

Ms Poon discovered that the cups, which were coming from Asia, would not be ready in time for the event. “We had to throw that plan out the window,” she says.

Instead, she and her team managed to source generic replacements for the shop from a UK-based supplier, which they then stamped with the Alpaca logo. Ms Poon says these cups also better meet the brand’s values as “they’re plastic-free and compostable as well”.